Overview

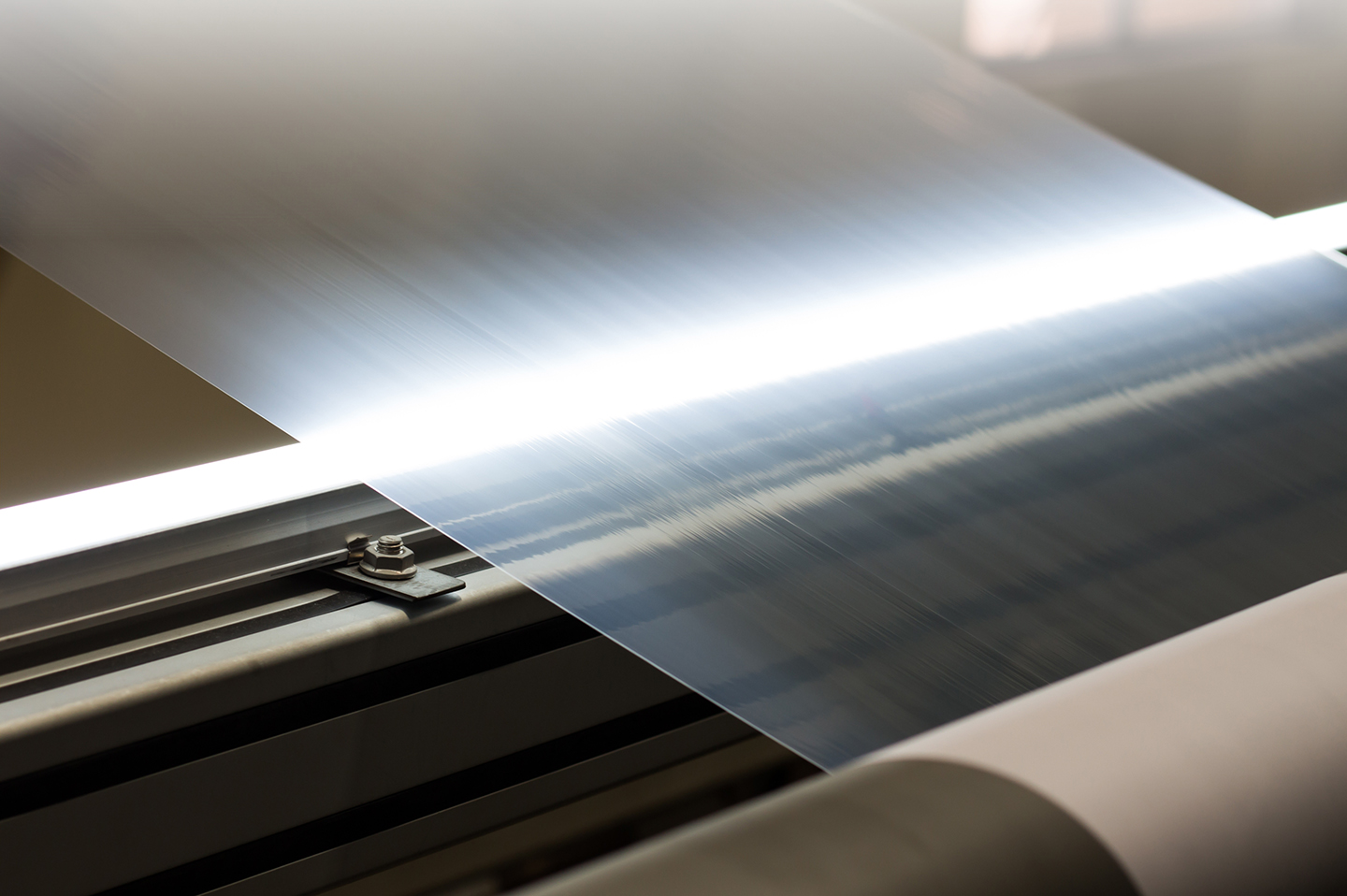

Automated Inspection system for continuous webs

It is essential to find defects early in the manufacturing process to avoid waste and deliver high quality products. Increasing demands are being placed on manufacturers to boost efficiency and improve quality for defect-free product.

QVision Surface Inspection System is an optical quality inspection system that can be installed on a production line to detect surface defects in real time. The system enables manufacturers to reduce waste and downtime on their production lines and also to take corrective action to eliminate defective material before it is sent to customers.

See one of our installations in action

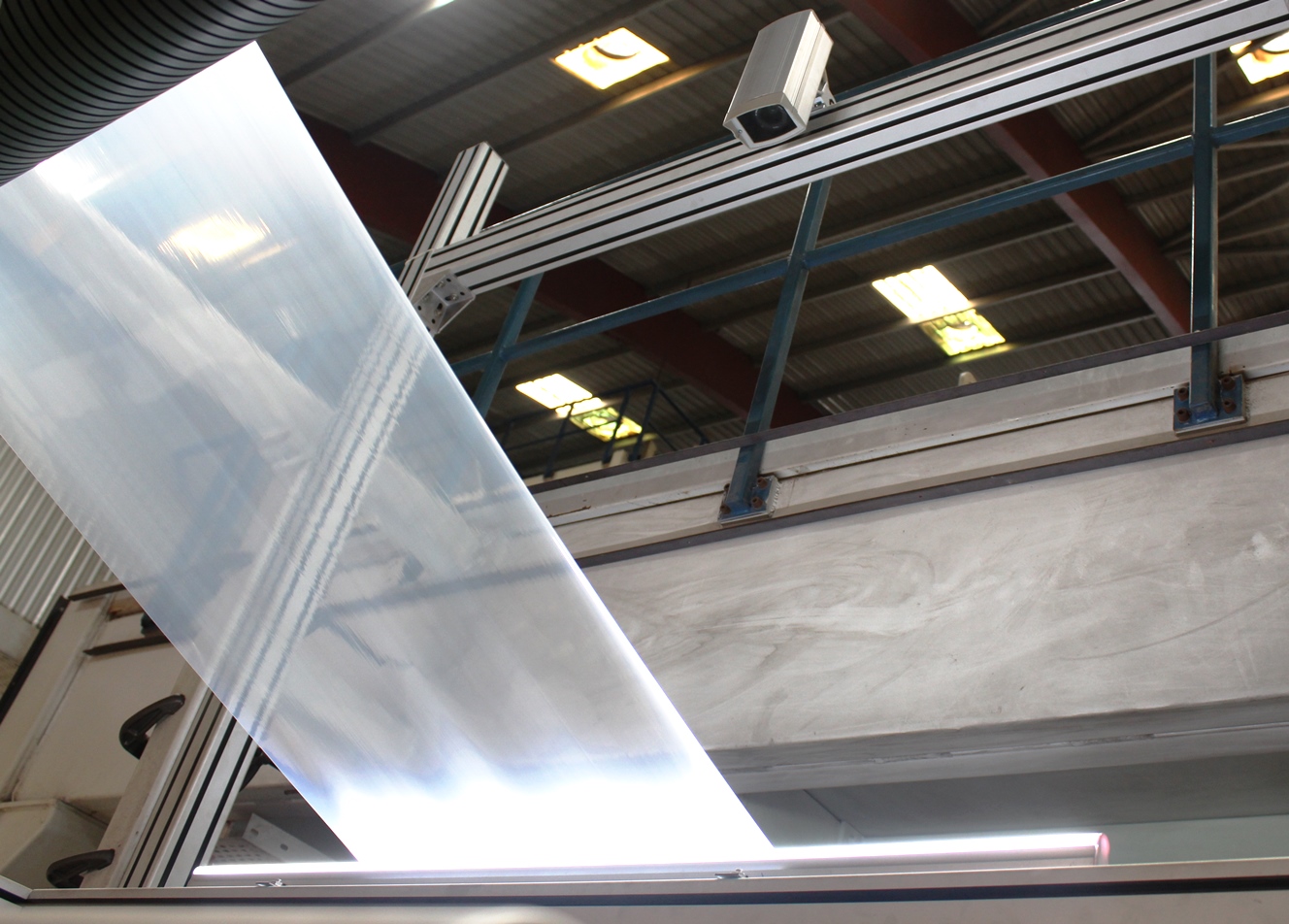

Q-Surface

Surface inspection of plain substrates

Inspection surfaces

- Transparent or opaque substrate

- Plain, coated or laminated surfaces

- Film, sheet, foil, metal, paper or fabric

Compatible machines

- Multi-layer extrusion line

- Cast film / Sheet line

- Laminating / Coating machine

- Slitter / Inspection rewinder

- Doctoring machine

- Plating line

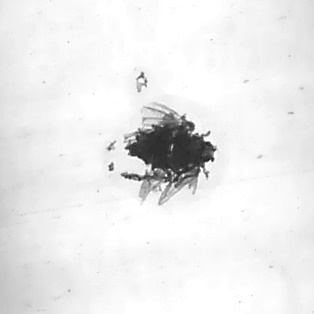

Burnt Particle

Bug

Gel

Hole

Coating Defect

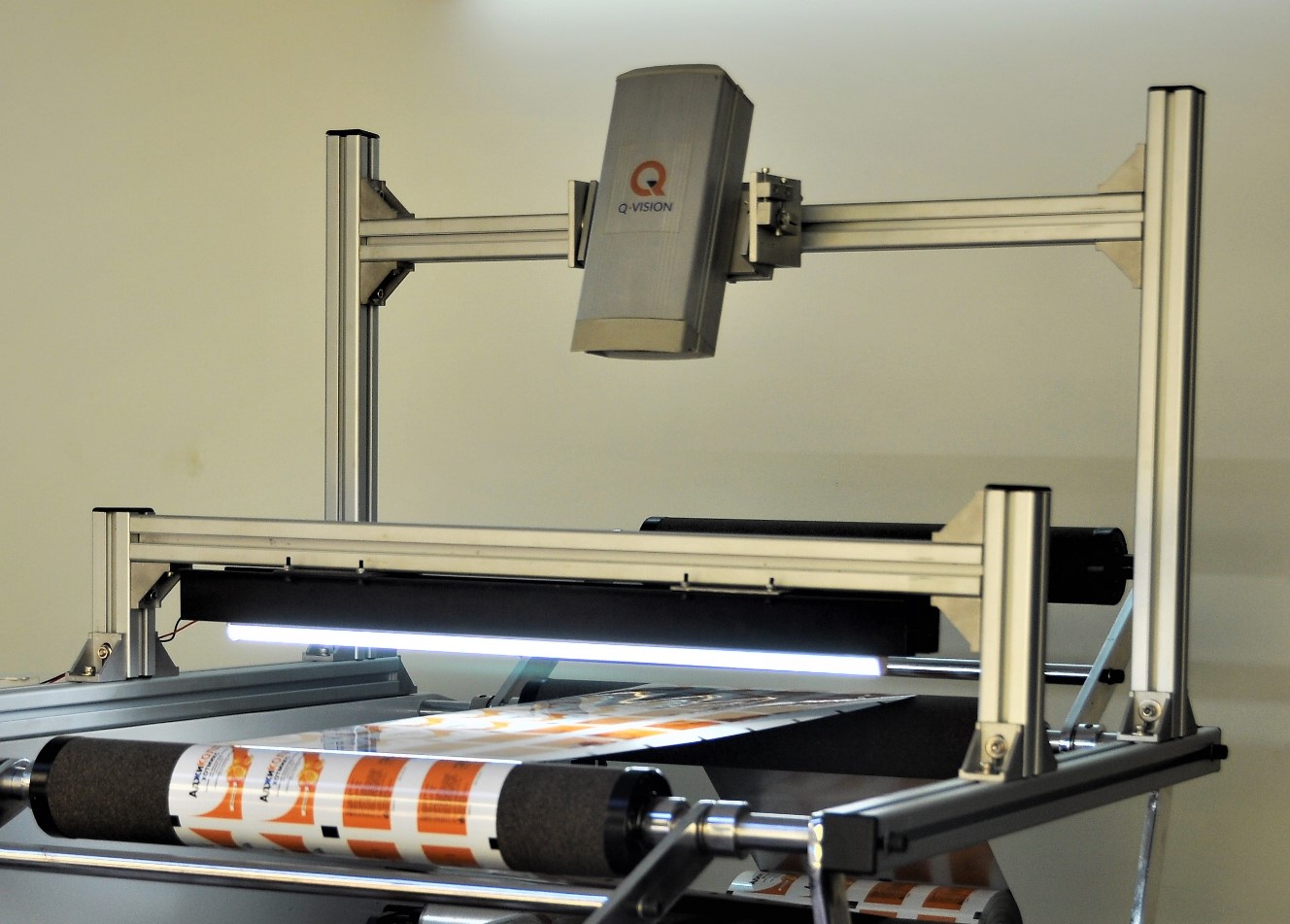

Q-Print

Print inspection of printed substrates

Inspection surfaces

- Transparent or opaque printed substrate

- Coated or laminated printed film/sheet/foil

Compatible machines

- Printing machine

- Laminating / Coating machine

- Slitter

- Inspection rewinder

- Doctoring machine

Mis-print

Registration

Wrinkle

Black spot

Dirt

Benefits

QVision Web Inspection System offers a Wide Range of Benefits

![]()

Reduce Customer Claims

Ensure 100% inspection and removal of critical defects

![]()

Roll Grading

Grade rolls based on type and frequency of defects for different market segments

![]()

Improve Production Efficiency

Make quick process corrections when predefined defect criteria triggers alarms

![]()

Upgrade Production Infrastructure

Automate your quality control process by avoiding error prone human inspection

![]()

Quick ROI

Our web inspection system offers excellent value and a quick return on investment

![]()

Customer Compliance

Comply with your customer’s highest quality standards and stringent audits

Applications

Globally used In High Quality Manufacturing

Any material that is continuously manufactured in flat and wide form factor can be scanned for surface defects using a web inspection system. These systems are widely used on extrusion lines, sheet lines and coating lines that manufacture films and sheets of the highest quality.

- Extruded Film Inspection

- Speciality and Hygiene Film Inspection

- Medical and Pharmaceutical Film Inspection

- Metal Inspection

- Paper Inspection

- Solar Cell(PV) Backing Sheet Inspection

- Laminates and Coated Substrate Inspection

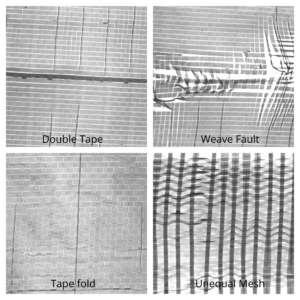

- Woven fabric (functional textiles) Inspection

We understand the need to evaluate the inspection system for a specific application. Therefore we have set up a demo system in our lab on a doctoring machine. Send us a sample roll to arrange a live demo and validate defect detection on the target substrate

Extruded Films

Laminated Films

PVC Films

Poly-carbonate Sheets

Metal

Paper

Solar Films

Woven Fabric

Features

A Few Key Features of QVision Surface Inspection

Customized Solution with High Quality Components

- Integrated system specially designed to suit your application

- High resolution industrial line-scan camera and lens

- Bright LED illumination and industrial workstation

Defect Identification

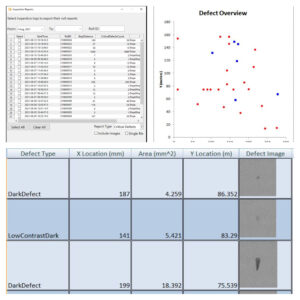

- Photo, type, size and location of each defect stored in database logs

- Specify criteria to segregate critical defects

- System can be trained to classify application specific defects

Defect Visualization and Reporting

- Live web display and system status

- Historical records available for future analysis and traceability

- Reports with filters to triage defects

Automation Interface and Alarms

- Make quick process corrections when alarm for critical defects are generated

- Trigger downstream machinery like taggers/labelers and sorting gates

- Automated roll changes ensures sync with production machine

Pricing

QVision Systems Give Quick ROIs By Offering Great Value

Team

We engineer smart solutions to help our customers improve their products

QVision was born out of Anand Group that has provided engineering services to several industries like plastics, paper and textile since 1975. We are a young establishment passionate about developing smart machine vision solutions for the manufacturing sector.

Akshat Kapadia (Founding Partner) – Akshat is a managing partner at Anand Group and has several years of experience in developing machine vision solutions. He worked at MathWorks, USA with various groups like Software Development, Application Engineering, Consulting and Marketing. Previously he worked for Whirlpool Research and Engineering Research Center (ERC) at the University of Michigan. Akshat has a Masters in Electrical Engineering specializing in Signal and Image processing from University of Michigan – Ann Arbor, USA

Anuj Nanavati (Founding Partner) – Anuj is a Managing Partner at Anand Group and is in charge of business development for manufacturing and services. He mentored early stage startups on User Experience and Customer Acquisition. Previously he worked for Nvidia, USA as a User Experience Researcher contributing to their software design. Anuj has a Masters in Information Sciences from University of Texas – Austin, USA.

Amol Nanavati (Founding Partner) – Amol is a Managing Partner at Anand Group and heads the Engineering department . He has 20+ years of experience in production and manufacturing. Amol has previously worked at Premier Automobiles Ltd in the Machine Tools department. He has a Bachelors in Mechanical Engineering from University of Pune.

Contact us

Let's discuss your business case and solve your inspection challenge

QVision Systems

5/6 Adarsh Estate,

Nr Chakudia Mahadev,

Rakhial, Ahmedabad 380023 (Gujarat) India

M : + 91 9909008574 /+ 91 8849486225

Tel:+ 91-79-22760590 / 22748318

Email : [email protected]